A stock level, or inventory level, is the number of units of a specific product a retailer has on hand. These items may be kept in physical stores or offsite storage facilities. A solo ecommerce store owner might keep stock at home to cut down on storage costs or partner with a dropshipping supplier that stocks the products and ships them to customers. Maintaining optimal inventory levels is easier when your lead times are shorter — or at least reliable. That way, when you order replenishment, you can count on when they’ll arrive. Setting minimum stock levels is essential to keeping customers happy and maintaining positive cash flow.

More essential inventory control terms to know

The minimum stock level ensures that operations continue smoothly even if there are unexpected fluctuations in demand or supply. For example, if a retail store determines that its minimum stock level for a specific shoe model is 20 pairs, they should reorder the item when the inventory reaches this number. The dangers of falling below the minimum stock level are evident — dissatisfied customers, strained relationships, and missed sales opportunities.

Minimum Stock Level: Definition and Explanation

- Safety stock is the extra inventory you keep on hand to protect against demand and supply chain uncertainty.

- While inventory management strategies differ for every company, a few best practices are proven to optimize inventory levels.

- For instance, if the software indicates 60 units on hand but an audit reveals 50, businesses can replenish to the optimal level and investigate missing units promptly.

For peak seasons like BFCM and Christmas, forecasting allows you to create a precise inventory plan to maintain balanced stock levels. Fabrikatör also enables you to use data from the same period in previous years, making your stock planning even more accurate. This way, you can manage your eCommerce store effectively without facing overstock or stockouts.

Ask Any Financial Question

Increase your security and become more cost effective with cloud-based inventory management. This is the lowest quantity of an item that customers have purchased within a specific period, often during off-peak times. For instance, if a toy store sells up to 100 units of a popular toy during the holiday season, that’s the maximum consumption. This is the highest quantity of an item a store has sold within a specific period, often during peak demand times. This is the average quantity of an item a store sells within a specific period under regular business conditions. To use this method, you must first determine how many units of a product are demanded each day, week, or month.

Refine warehouse operations

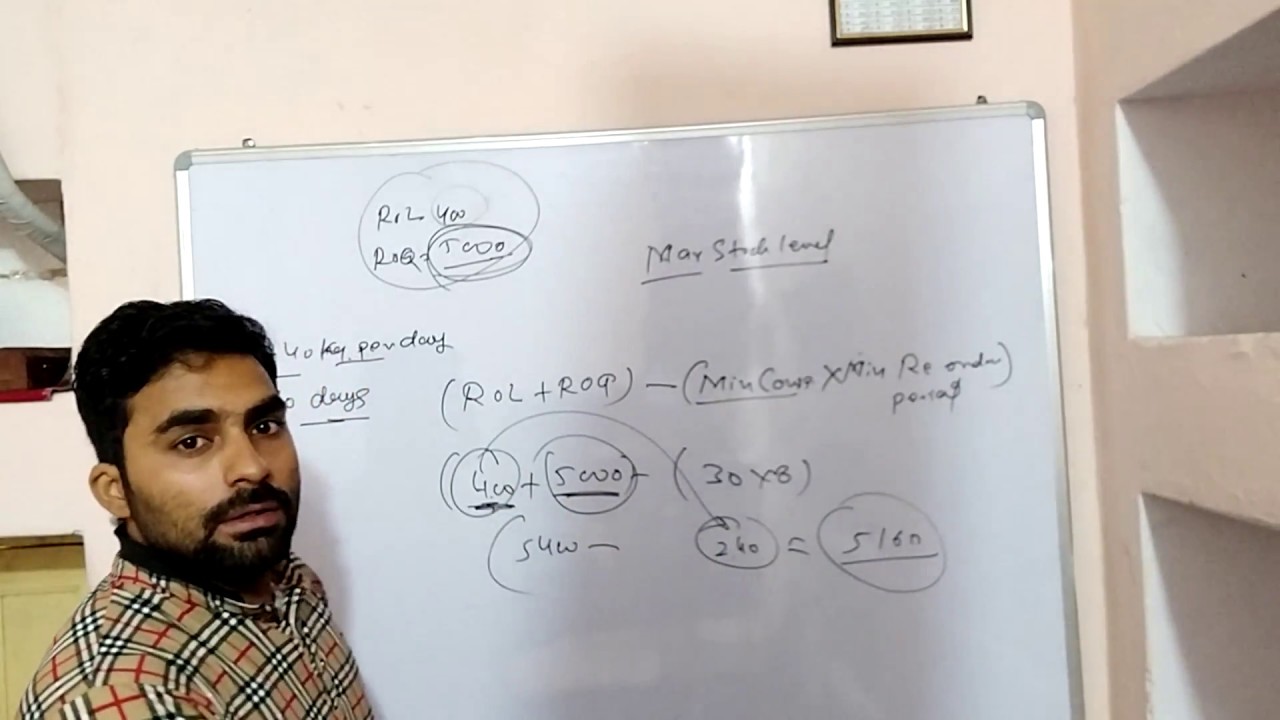

Knowing the normal, minimum, and maximum sales for product stocks will give you a strong foundation for fixing the minimum stock level. Since we know the above mentioned formula for calculating the minimum stock level, let’s start by calculating the reorder level first. In the event of unexpectedly high orders, this minimum stock level will allow you to meet demand for at least another three days without any problems, thus ensuring a constant standard of service. By using the information in this blog post, you can ensure that you always have enough products in stock to meet customer demand. Maintaining the right amount of inventory allows a company to operate more effectively and capably meet customer demand.

How To Calculate And Maintain Optimal Inventory Levels

If you’d like to see how it works in detail, take 30 minutes to see Fabrikatör in action. ✨ Long story short, incorporating Fabrikatör into your eCommerce store’s inventory planning and management process makes the entire inventory process much easier for yourself and your team. You no longer have to constantly check inventory data you can’t be sure is accurate or create last-minute purchase orders to avoid stockout and overstock. Running out of stock means missed sales opportunities and unhappy customers. Especially during a peak season like BFCM, out-of-stock issues can result in lost revenue and damage your brand’s reputation. Conversely, excess stock ties up capital and increases storage costs, impacting the profitability of your eCommerce business.

Any inventory beyond the maximum recommended level can cause a strain on resources and end up as an overstock. On the other hand, too little inventory can lead to lost sales and additional expenses for rushed restock orders. With the ideal number of products on hand, a business can operate more efficiently, only spending what it needs and generating are there taxes on bitcoins more profit. Dynamic reorder points and safety stock calculations can help businesses quickly adapt inventory strategies to changing demand. Raw materials include the components needed to support the manufacturing process. The Materials Requirements Plan (MRP) calculates raw materials based on the production schedule and Bills of Material (BOMs).

Today, innovative tools empower businesses to take control of their stock levels, including minimums. As you probably noticed, calculating and maintaining optimal inventory levels is a time-consuming task. That’s because you’re constantly selling through and replenishing the stock you have in your warehouse. This eliminates excess inventory (so you’re not stuck paying storage costs), reduces your insurance liability, and keeps you from collecting dead stock. Optimal inventory levels are somewhere between your minimum and maximum levels. And you need to calculate this number to, well, maintain optimal inventory levels.

This ties up cash you could be using for other things, like marketing or new product development. Plus, all that extra stock takes up space, which means higher storage costs. As sometimes the minimum inventory levels can be a slumbering factor in your strategy. Alternatively, an ops optimization tool like Cogsy will automatically calculate safety stock into your optimal stock levels and have your POs reflect that information.

At Interlake Mecalux, we are specialists in pallet racking, picking shelves, automated warehouses and logistics software. Think of them as a proactive measure to maintain accurate stock records and prevent operational disruptions. Having a WMS makes it possible for the installation to process unplanned receipts and organise the subsequent location management of these goods. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing. Now that you understand the importance of these levels, let’s explore how to calculate them.